Casey Esbensen

0 Course Enrolled • 0 Course CompletedBiography

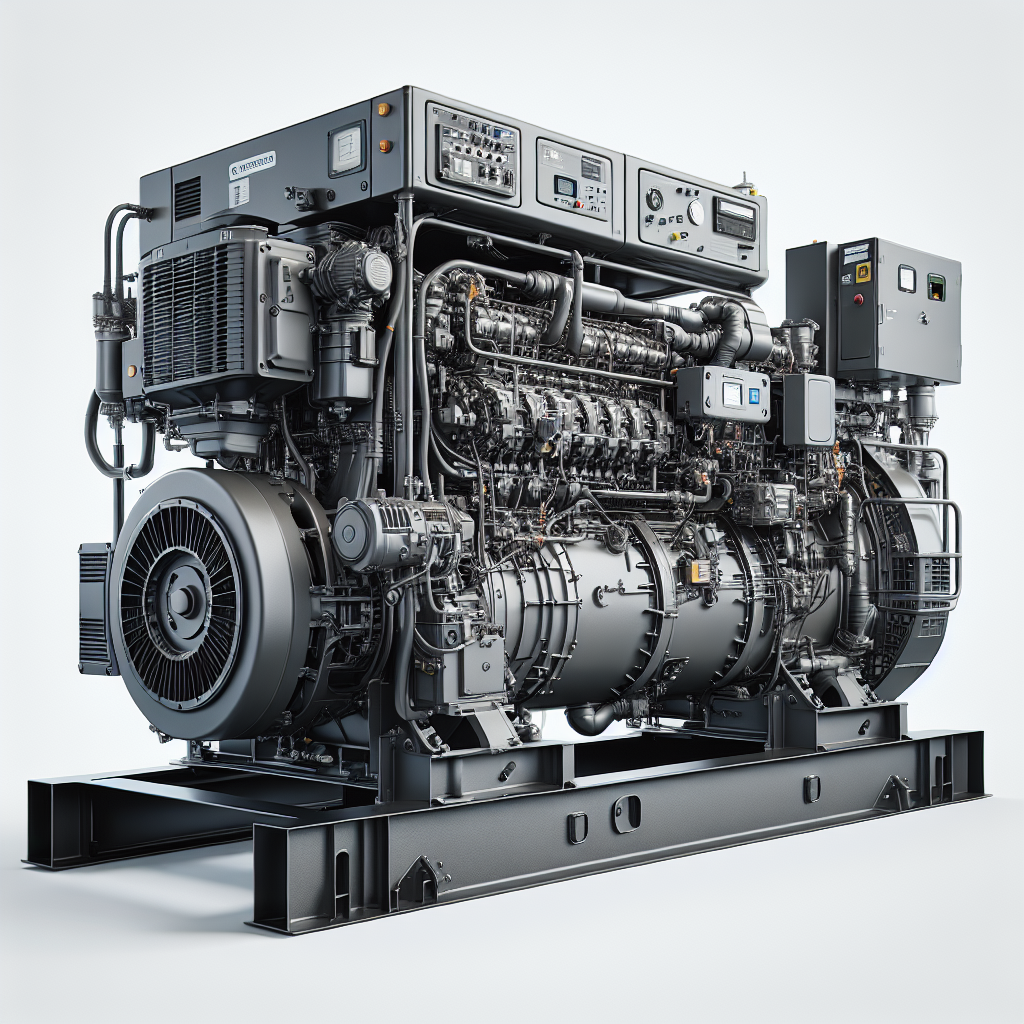

Ensuring Reliable Power Supply with Diesel Generators for Site Acceptance Testing

Introduction

Site acceptance testing is a crucial step in the deployment of various systems and equipment, ensuring that they meet the specified requirements and function as intended. One of the key considerations for successful site acceptance testing is the availability of a reliable power supply. Diesel generators play a vital role in providing backup power during site acceptance testing, ensuring uninterrupted operations and accurate assessment of equipment performance. This article explores the importance of diesel generators in site acceptance testing and provides insights into their selection, installation, and maintenance.

Importance of Diesel Generators in Site Acceptance Testing

Site acceptance testing involves the validation of systems, equipment, or infrastructure under real-world conditions to ensure compliance with technical specifications and performance requirements. These tests often require continuous and stable power supply to operate the equipment being tested and to record accurate data. Any interruption or fluctuation in power supply can lead to inconclusive test results, delays in the testing process, and potential risks to the equipment under evaluation.

Diesel generators are widely used in site acceptance testing due to their reliability, fuel efficiency, and ability to provide backup power in remote or off-grid locations. These generators are capable of delivering a consistent power output over an extended period, ensuring that the testing process can proceed without disruptions. The robust design of diesel generators makes them suitable for harsh environmental conditions, making them ideal for outdoor testing scenarios.

Key Considerations for Selecting Diesel Generators for Site Acceptance Testing

When selecting a diesel generator for site acceptance testing, several key considerations must be taken into account to ensure optimal performance and reliability. These considerations include:

1. diesel generator efficiency : The power output of the diesel generator should match the requirements of the equipment being tested. It is essential to calculate the total power consumption of all devices connected to the generator to determine the appropriate power rating.

2. Fuel Efficiency: Diesel generators are known for their fuel efficiency compared to other types of generators. Opt for a generator with a fuel-efficient engine to minimize operational costs during the testing process.

3. Portability: Depending on the testing location and setup requirements, portability may be a crucial factor in selecting a diesel generator. Choose a generator that is easy to transport and set up at the testing site.

4. Noise Levels: Consider the noise levels produced by the diesel generator, especially if the testing site is in a residential area or noise-sensitive environment. Select a generator with soundproofing features to minimize noise emissions.

5. Emissions Compliance: Ensure that the diesel generator complies with environmental regulations and emissions standards to minimize its impact on the surrounding environment.

Installation and Setup of Diesel Generators for Site Acceptance Testing

Proper installation and setup of diesel generators are essential to ensure their optimal performance during site acceptance testing. The following steps should be followed when installing a diesel generator for testing purposes:

1. Site Assessment: Conduct a thorough assessment of the testing site to determine the best location for placing the diesel generator. Consider factors such as ventilation, access to fuel supply, and proximity to the equipment being tested.

2. Fuel Storage: Ensure an adequate supply of diesel fuel is available on-site to power the generator throughout the testing period. Store the fuel in a safe and secure location away from potential hazards.

3. Electrical Connections: Connect the diesel generator to the electrical distribution panel using appropriate cables and connectors. Ensure that the electrical connections are properly grounded to prevent electrical hazards.

4. Startup Procedure: Follow the manufacturer's instructions for starting up the diesel generator, including priming the fuel system, activating the engine, and monitoring the output voltage and frequency.

5. Load Testing: Conduct load testing on the diesel generator to verify its performance under varying load conditions. Monitor the generator's output voltage and frequency to ensure stability and consistency.

Maintenance and Troubleshooting of Diesel Generators

Regular maintenance and troubleshooting are essential to keep diesel generators in optimal condition for site acceptance testing. The following maintenance tasks should be performed at regular intervals to ensure the reliability and longevity of the generator:

1. Fuel System Inspection: Check the fuel system components, including the fuel tank, filters, and injectors, for any signs of damage or contamination. Replace fuel filters as recommended by the manufacturer.

2. Oil and Filter Changes: Regularly change the engine oil and filters to maintain proper lubrication and prevent engine wear. Follow the manufacturer's recommendations for oil change intervals and oil type.

3. Cooling System Maintenance: Inspect the cooling system components, such as the radiator, hoses, and coolant levels, to prevent overheating and ensure efficient engine operation.

4. Battery Health Check: Test the battery voltage and condition regularly to ensure reliable engine starting. Replace the battery if it shows signs of weakness or deterioration.

5. Electrical System Inspection: Inspect the electrical connections, wiring, and components for signs of wear or damage. Tighten loose connections and repair or replace faulty components as needed.

In case of any issues or malfunctions with the diesel generator during site acceptance testing, the following troubleshooting steps can be taken to identify and resolve the problem:

1. Check Fuel Supply: Verify that an adequate supply of diesel fuel is available and that the fuel lines are not clogged or blocked. Prime the fuel system if necessary to remove air bubbles.

2. Monitor Engine Parameters: Monitor the engine parameters such as temperature, oil pressure, and exhaust emissions to identify any abnormal readings that may indicate a problem.

3. Inspect Filters: Check the fuel and air filters for blockages or contamination that may restrict fuel flow or airflow to the engine. Replace the filters if necessary.

4. Test Electrical Systems: Verify the integrity of the electrical connections, fuses, and relays to ensure proper electrical supply to the generator. Check the battery voltage and connections for any issues.

5. Consult Manufacturer Guidelines: Refer to the manufacturer's maintenance manual and troubleshooting guide for specific instructions on diagnosing and resolving common generator issues.

Conclusion

Diesel generators play a critical role in providing reliable backup power for site acceptance testing, ensuring uninterrupted operations and accurate assessment of equipment performance. By considering key factors such as power output, fuel efficiency, portability, noise levels, and emissions compliance, organizations can select the most suitable diesel generator for their testing requirements. Proper installation, maintenance, and troubleshooting practices are essential to maximize the performance and longevity of diesel generators during site acceptance testing, minimizing downtime and ensuring successful testing outcomes. With the right diesel generator in place, organizations can conduct site acceptance testing with confidence and achieve their project objectives efficiently and effectively.